Kanga Potash

Project

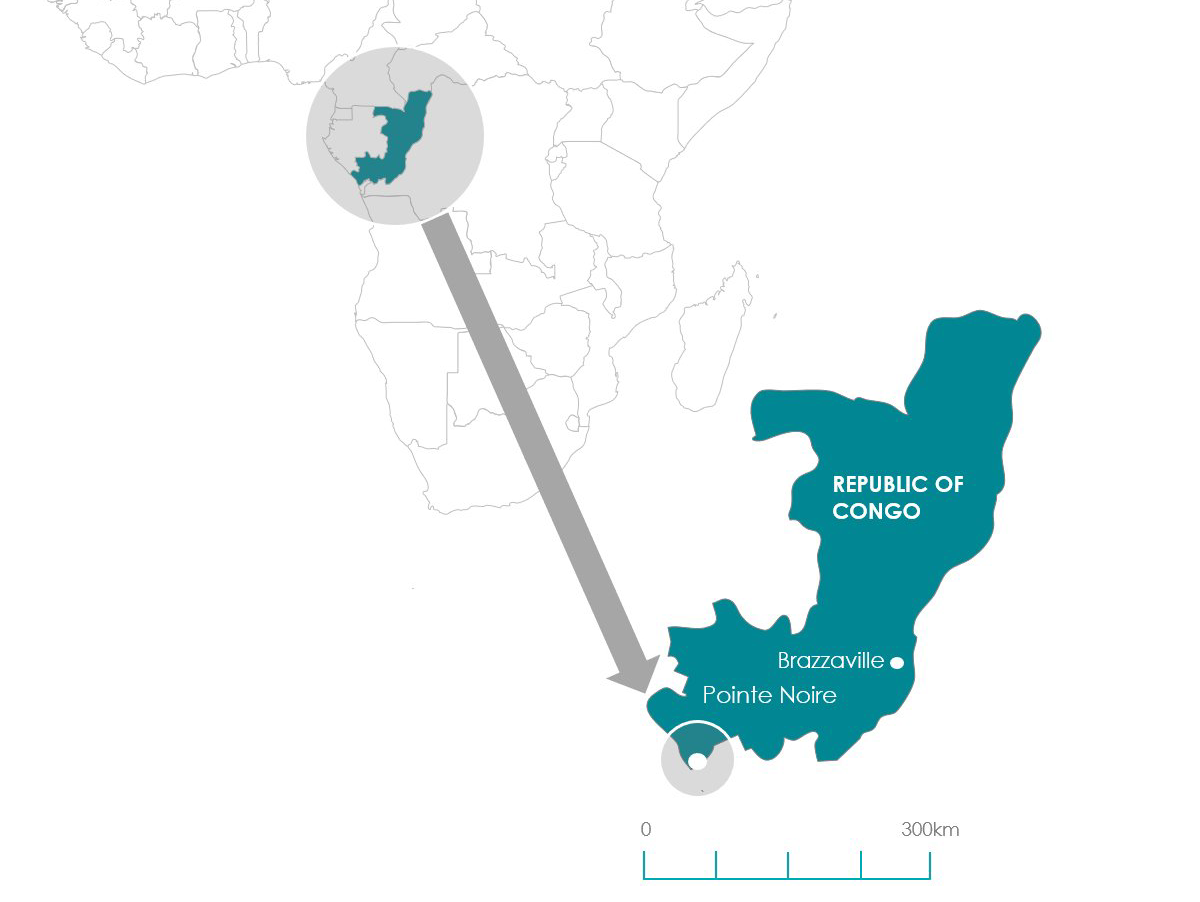

Republic of Congo

SARMIN Minerals Exploration ("SME") holds two exclusive exploration licenses Kanga and Loango • The Kanga project has the thickest sequence of minable potash seams ever drilled anywhere in the world, contained within a paleo-embayment in a coastal position with the senior management team that has acquired a wealth of experience in the potash and other industries in the Republic of Congo since 1998. Read more

UNIQUE AND POWERFUL FEATURES

SME holds two exclusive exploration licenses Kanga and Loango covering a total surface area of 760 km2 bordering the sea and 50 km from Pointe-Noire, covering all known locations of onshore ultra-thick seams

An invest opportunity into a truly unique potash deposit

in the Republic of Congo, that will support the development of an industry disruptive, Tier 1 project

Basin-wide modelling identified paleo-embayment of thick potash seams over the project area. The

thickest sequence of minable potash seams

ever drilled anywhere in the world, contained within a paleo-embayment in a coastal position

NI 43-101 compliant Indicated and Inferred Resource in excess of

12Bt carnallite with only 15 km2

(indicated) explored to date and considerable expansion opportunity. In excess of 210 meters of mineable potash contained in 13 mining horizons.

The Project is

significantly advanced with PFS completed by top industry consultants Novopro Projects Inc., Ercosplan and WSP in September 2018. Multiple development options

of 400K tpa, 800K tpa and 2.4M tpa MOP have been assessed, all returning highly compelling economics due to very competitive cash costs and low capex intensity

you can read more at www.kangapotash.com